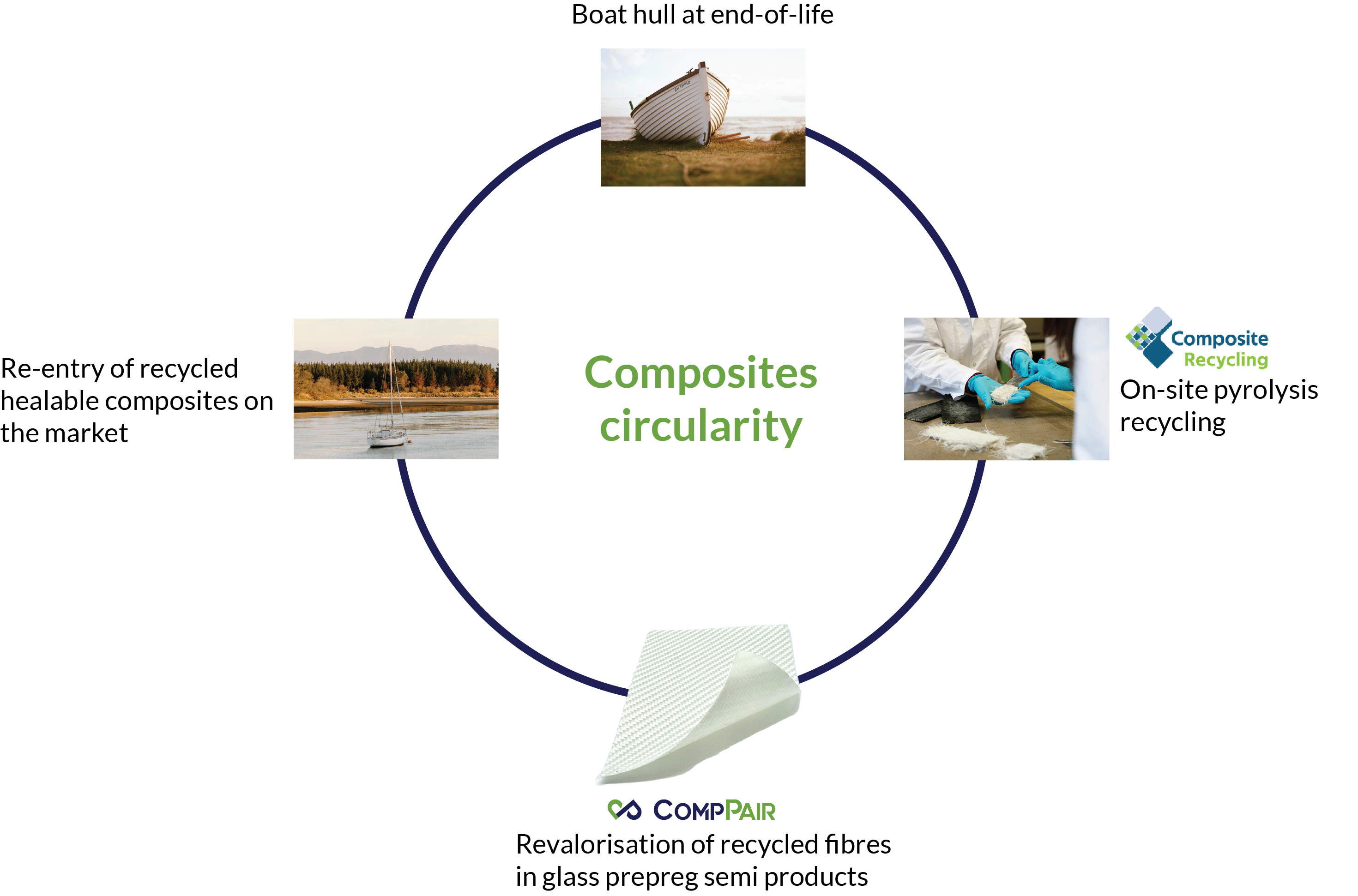

Closing the loop with a healable composite that is both recycled and recyclable!

In line with the sustainable vision of both companies, CompPair is working with Composite Recycling to reduce the carbon emissions of our products even further! Our aim is to bring circularity to the composites industry, and this collaboration brings us one step closer to making that a reality.

Our collaboration

Composite Recycling has the potential to confront a large issue present in all industries using composites. By recycling fibres from boat hulls, we can reintroduce the composites onto the marine market and give the materials a second life. We have combined Composite Recycling’s recycled glass fibres with CompPair’s healable resin, to produce a healable recycled prepreg. Our skilled engineers have now completed tests pairing their recycled glass fibres with our self-healing resin, to make a very special super-green prepreg!

Composite Recycling has developed a unique process to recover glass fibres from composite materials in an economically viable way. Together with the Laboratory for Processing of Advanced Composites (LPAC) of EPFL, they are scaling up their process to treat composite wastes piling up in the marine industry. Composite Recycling’s mission is to recycle glass fibre reinforced plastic coming directly from waste streams such as boat hulls, reclaiming the glass fibres and repurposing them into new fiber glass production, enabling a new range of “green fiberglass” products.